II.

The Home of the Macon

Hangar 1

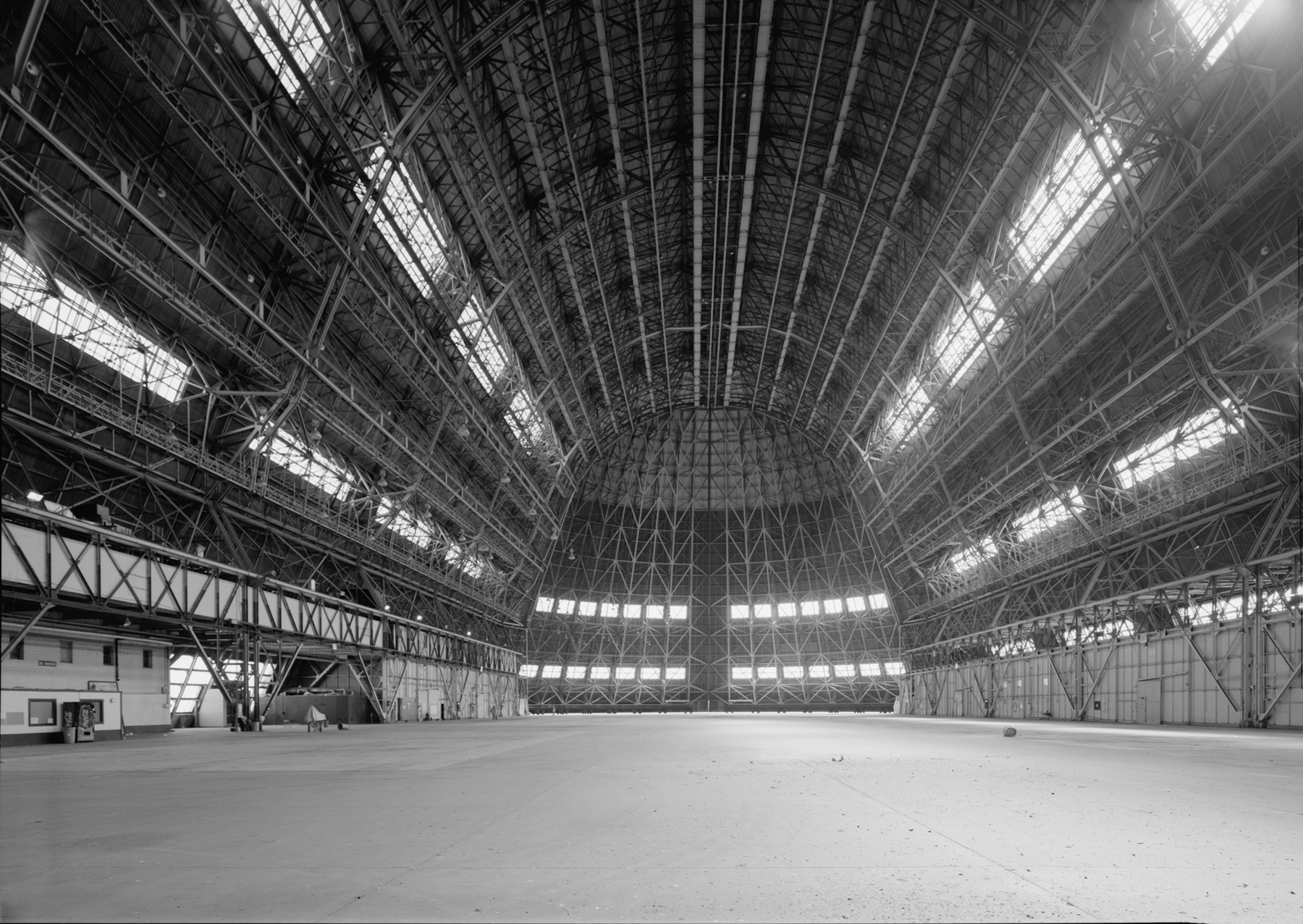

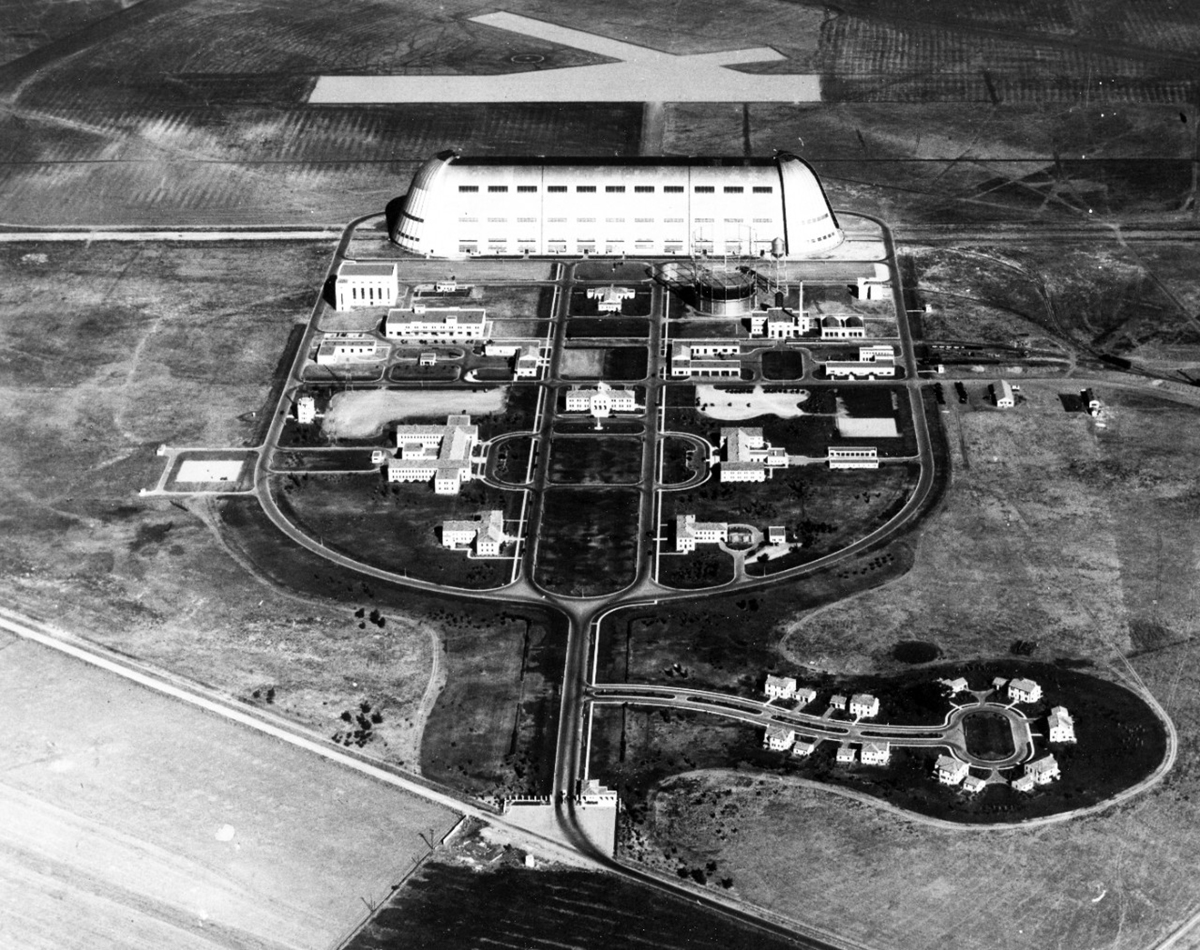

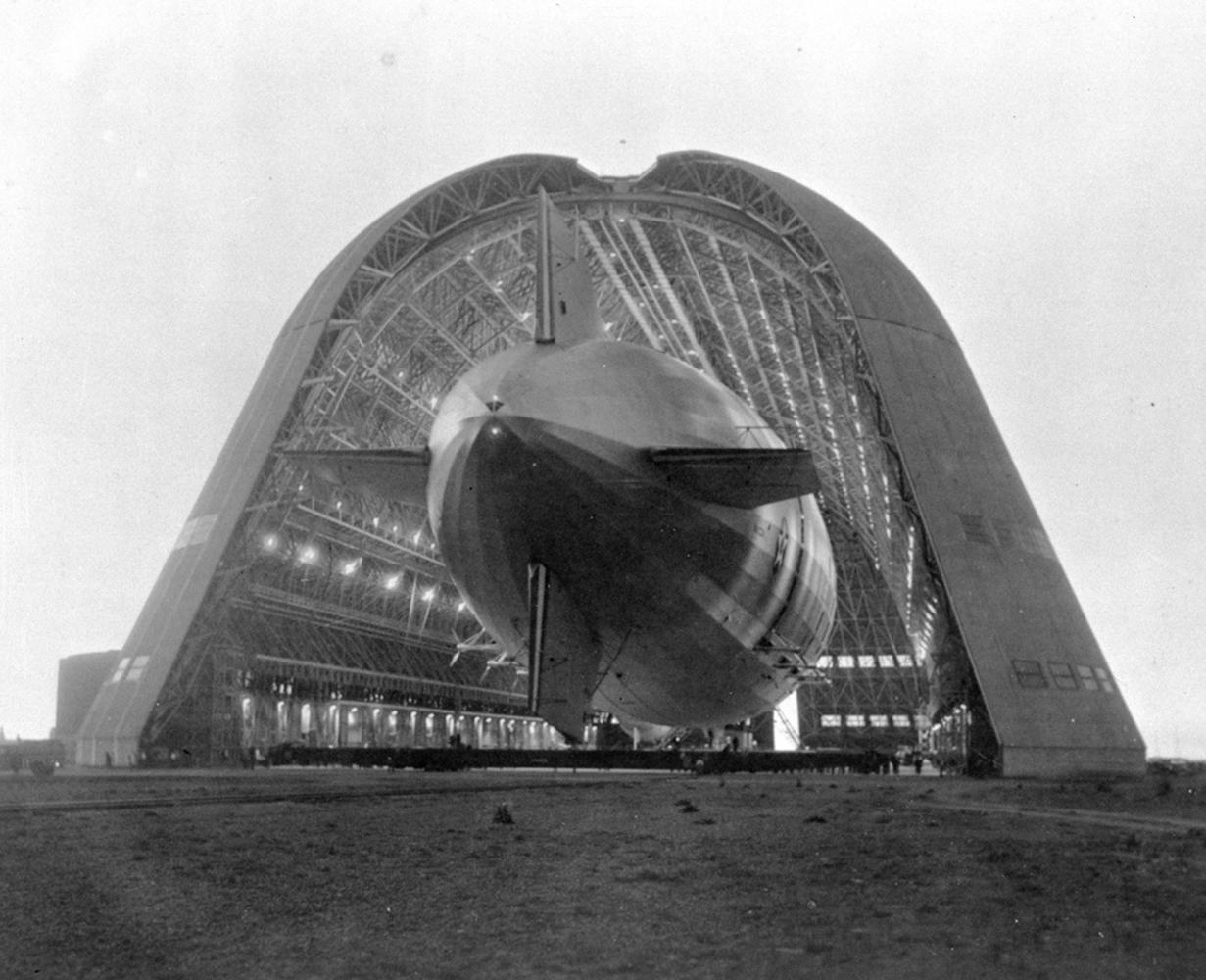

The awe-inspiring rigid airship, named the USS Macon, was 785 feet long, 132 feet wide, and 146 feet tall. The Department of the Navy Bureau of Yards and Docks designed an enormous 1,113-foot-long hangar with an 8-acre footprint to protect the dirigible at Naval Air Station Sunnyvale. Completed in 1933, its Streamline Moderne architectural style mirrored the Macon’s sleek lines and metallic finish. Hangar 1, and a nearly identical structure in Akron, Ohio, where the Macon and the USS Akron were built, are two of the largest clear-span, or column-free, interior spaces in the United States.

The construction of Hangar 1 began in 1931. It cost $2.25 million and required about 20,000 tons of steel and approximately 25,500 cubic yards of concrete. The structure consists of 14 hinged steel parabolic trusses stabilized with x-bracing. Upper areas are accessed via catwalks interwoven with the trusses. Two- and three-level spaces along the east and west walls contained machine shops, maintenance shops, laboratories, offices, classrooms, and storage rooms. The silver-painted exterior of Hangar 1 was originally made of an innovative, fire-resistant material called Robertson Protected Metal (RPM). The uppermost portion of the hangar’s exterior was clad in redwood sheathing covered with RPM. Long bands of rectangular, steel-framed windows provide the interior with natural light.

Pedestrian and vehicular doors line the east and west facades. Huge, 500-ton, "orange peel" doors, located at each end of the building, allowed the Macon to enter and exit the hangar with ease. A nine-story mooring mast pulled the dirigible along tracks that extended outside to mooring circles located on either end of the structure.

Hangar 1 was listed in the National Register of Historic Places in 1994, designated a Naval Historical Monument, and declared a California Historic Civil Engineering Landmark by the San Francisco section, American Society of Civil Engineers.

In 2002, it was determined that Hangar 1 contained asbestos, lead, and polychlorinated biphenyls (PCBs), which are potential health and environmental hazards. The Navy addressed those issues by preserving and decontaminating historic artifacts; removing the hangar’s roof, siding, windows, doors, and other exterior components, which were contaminated with toxic chemicals; demolishing the interior structures of the hangar; and coating the structure with epoxy to ensure the chemicals would not pose a risk. In 2022, a comprehensive remediation, clean-up, and restoration project was initiated to preserve the structure and establish a revitalized new era for Hangar 1.

Key Facts

Construction

1931–1933

Architects

Staff architects and engineers of the Department of the Navy's Bureau of Yards & Docks, Twelfth Naval District Public Works Office at San Bruno, California

Designer-in-charge

Rear Admiral A.L. Parsons,

Chief of the Bureau of Yards & Docks

Officer-in-charge of construction

Lieutenant Commander Earl L. Marshall

Principal designers

Ernest L. Wolf, civil engineer, Goodyear-Zeppelin Corporation of Akron, Ohio

Dr. Hugo Ekener, engineer, Goodyear-Zeppelin Corporation of Akron, Ohio

Architectural style

Streamline Moderne

Construction cost

$2.25 million

Contractors

Raymond Concrete Company:

general site grading, concrete slab floor and foundations, installation of tracks for the doors and the tug

Wallace Bridge & Structural Steel Company: steel frame

Siems-Helmers, Inc.: Robertson Protected Metal (RPM) wall cladding

E. C. Nichols: lights and power system

Otis Elevator Company: installation of the two parabolic-track elevators

Height

198 feet from the floor to the top of the trusses

Length

1,133 feet

Width

308 feet

Area of Building Footprint

323,062 square feet or approximately 8 acres

Construction type

Steel-frame

Original exterior skin

Fire-resistant Robertson Protected Metal (RPM)

Original exterior skin on uppermost 70 feet

Robertson Protected Metal (RPM) over 2-inch redwood sheathing

Original flat portion of roof

Redwood sheathing covered with five-ply roofing materials composed of layers of asphalt, felt, and gravel

Number of steel parabolic trusses

14

Foundation

Reinforced-concrete perimeter wall foundation with reinforced concrete pilings

Number of concrete piles

968

Floor

8-inch concrete slab

Weight of each “orange peel” door

500 tons

Time required for mechanical doors to fully open

12 minutes

Shenandoah Plaza

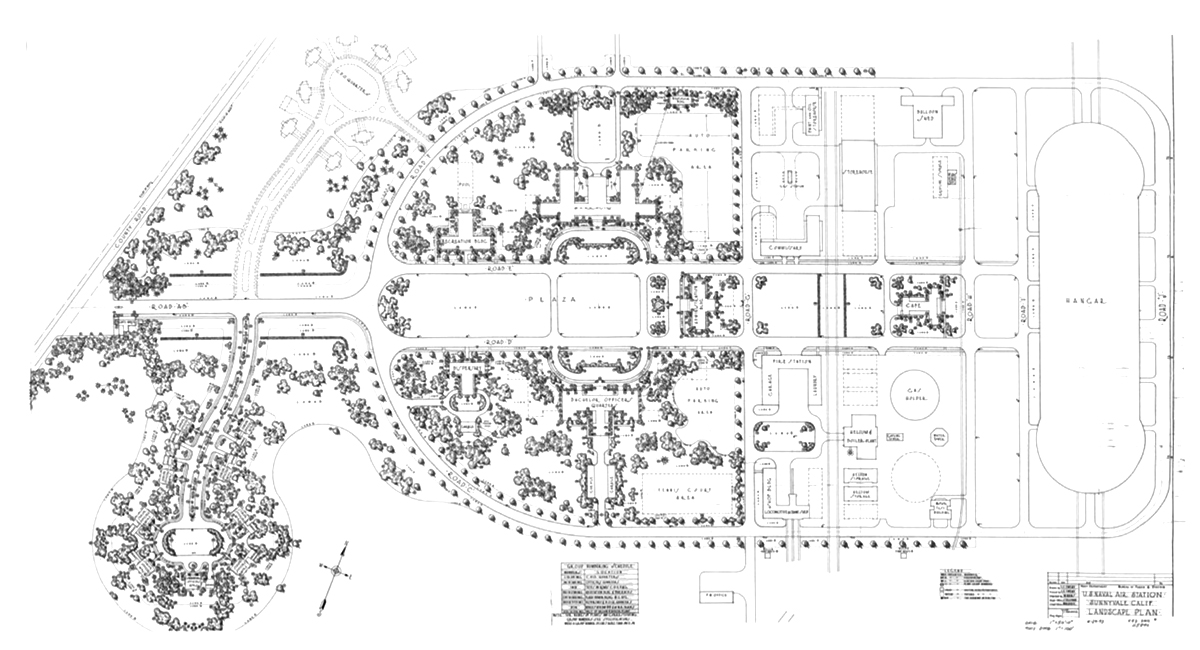

The plan of Hangar 1 was oriented parallel to the site’s prevailing winds, in order to aid the ascent and descent of the USS Macon. All of the other original facilities at Naval Air Station Sunnyvale, including administrative buildings, a hospital, and residences, were aligned with that main axis. The master plan, designed by the Department of the Navy Bureau of Yards and Docks, features a symmetrical configuration of elegantly ornamented Spanish Colonial Revival style buildings with cream-colored stucco facades and red-tiled roofs situated around a wide grassy mall, known as Shenandoah Plaza. The campus’s utilitarian structures feature an unadorned Streamline Moderne aesthetic. The contrast between the modern monumentality of Hangar 1 and the adjacent low-rise buildings creates a dramatic and memorable vision as one enters the main gate of Moffett Field. The Shenandoah Plaza Historic District, consisting of the elliptical shaped plaza, 22 buildings, including Hangers 1, 2, and 3, and their ancillary structures and roads, was added to the National Register of Historic Places on February 24, 1994. The listing was based on Criterion A: “for the association with coastal defense and naval technology that has made a significant contribution to the broad patterns of our history;” and Criterion C: “reflecting the distinctive type, period, method of construction and high artistic values that are represented in the 1933 station plan and buildings.”

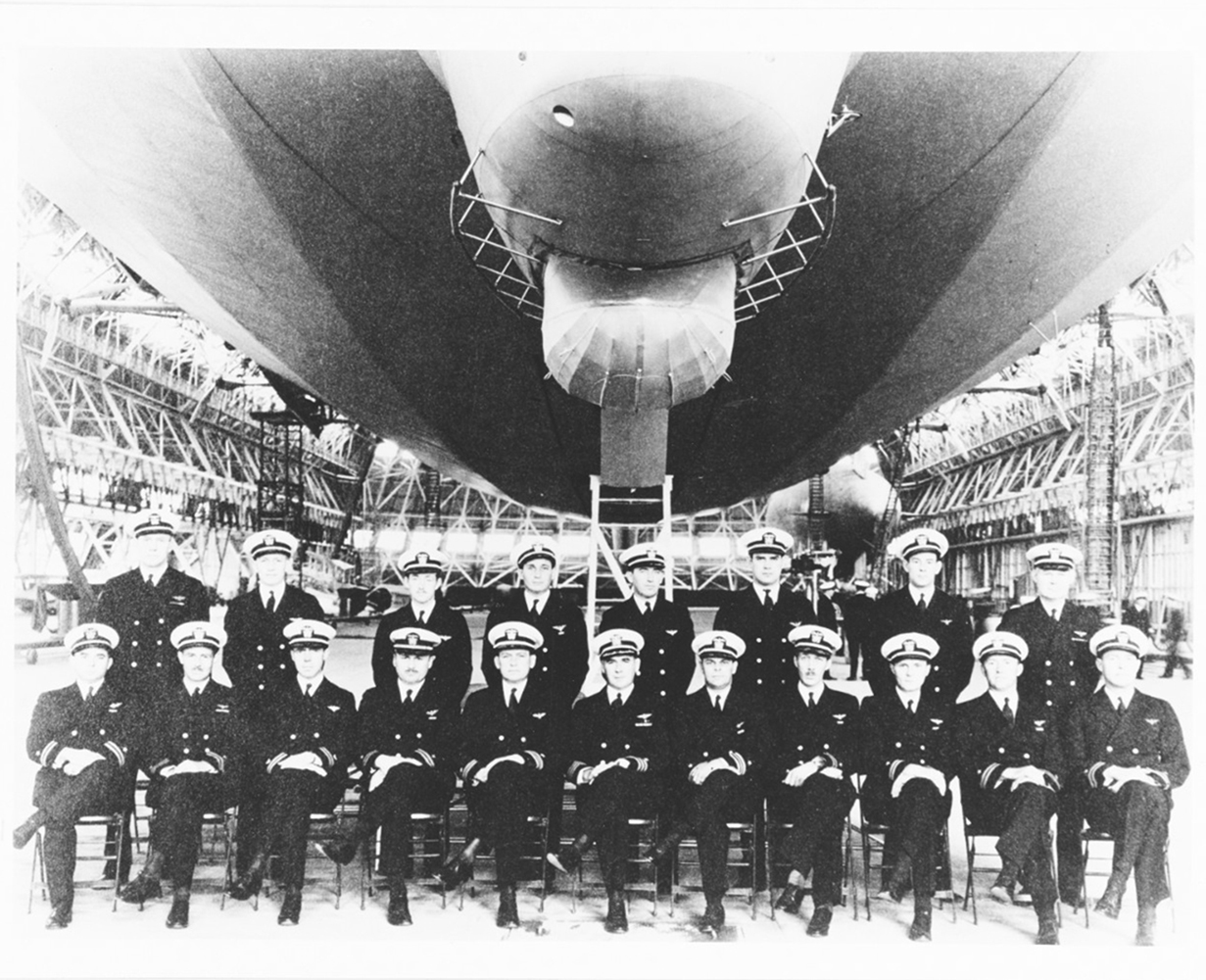

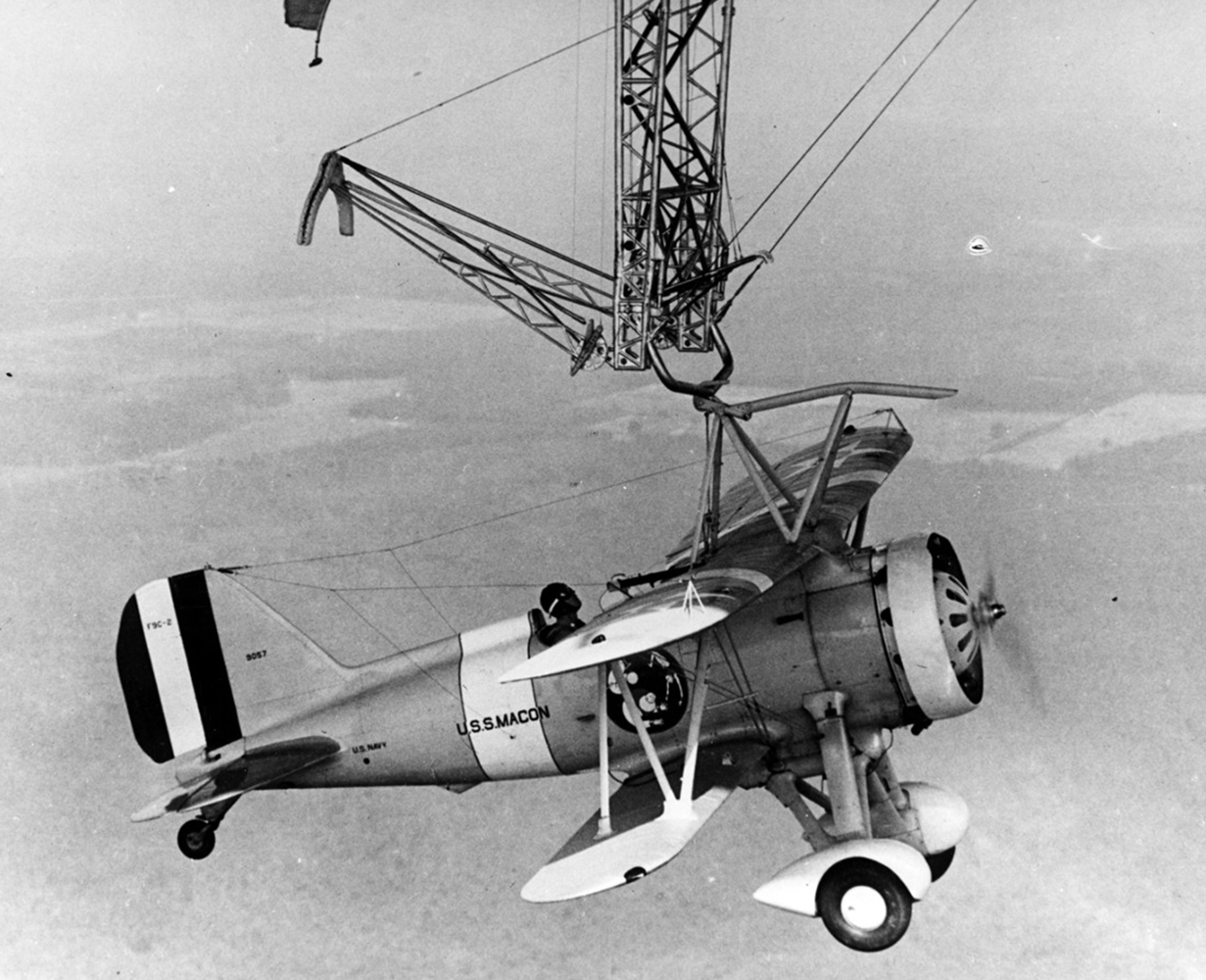

The USS Macon

The USS Macon (ZRS-5) rigid airship was created to help defend the West Coast from submarine attacks. Designed to be an aircraft carrier in the sky, its speed, silent motion, long range, and onboard Curtiss F9C Sparrowhawk fighter planes, which were dramatically deployed from its belly via a “trapeze” hook, allowed the Macon to patrol thousands of miles without refueling. Only 97.5 feet shorter than the RMS Titanic, the massive Macon captured the public’s imagination during its brief sixteen-month tenure of service.

The dirigible was constructed with four-sided, box-type, duralumin girders and “deep section” frames, or rings, which created its form. The crew moved throughout the spaces within its internal metal hull via catwalks, girders, and cables. The structure was covered in cotton cloth that was painted with a plasticized lacquer called “aircraft dope,” which was aluminized to deflect the sun’s rays and created a shimmering vision while the Macon cruised across the horizon.

Germany’s infamous Hindenburg Zeppelin was kept aloft with flammable hydrogen and met its scorching end at Lakehurst, New Jersey on May 6, 1937. American airships took flight using non-burning helium, a gas which only the United States possessed at that time. The USS Shenandoah and the USS Los Angeles, commissioned in 1923 and 1924, set high ambitions for the Navy’s new lighter-than-air (LTA) fleet. Both dirigibles were constructed in Germany and were a part of that nation’s World War I reparations to the United States. The Goodyear-Zeppelin Company of Akron, Ohio built the USS Akron in 1931 and the Macon in 1933.

Unfortunately, disaster struck nearly all of those enormous airships. The Shenandoah crashed in Noble County, Ohio on September 3, 1925. The USS Los Angeles was grounded in 1932 and was eventually dismantled in 1939. The Akron’s tragic final flight was on April 4, 1933 off the coast of Atlantic City, New Jersey. Due to a deferred repair to two of its damaged tail fins, the Macon plunged into the Pacific Ocean on February 11, 1935 during a storm near Point Sur, California. That devastating event compelled the United States Government to end its rigid airship program, and Naval Air Station Sunnyvale and Hangar 1 were transferred to the U.S. Army Air Corp on October 25, 1935. Six years later, the attack on Pearl Harbor would be the catalyst for the launch of a new lighter-than-air era of nimble blimp squadrons based in monumental wood hangars that were quickly constructed across the country.

The USS Macon

Key Facts

First Flight

April 21, 1933

Commissioned

June 23, 1933

Arrival at Moffett Field

October 15, 1933

Origin of Macon name

The largest city in the district of Georgia Representative Carl Vinson, Chairman of the U.S. House of Representatives Committee on Naval Affairs

Construction cost

$2,450,000

Construction location

Akron, Ohio

Builder

Goodyear-Zeppelin Co., a joint venture of the Goodyear Tire and Rubber Company of Akron, Ohio and the Zeppelin Company of Friedrichshafen, Germany

Length

785 feet

Width

132 feet, 10 inches

Range

6,835 miles

Ceiling

26,000 feet

Flight team

12 officers and 45 crewmembers

Number of Curtiss F9C-2 Sparrowhawk fighter planes that could be stored inside the Macon

5

Number of Browning 0.30-caliber machine guns

8

Fully loaded weight

400,000 pounds

Total number of flights

54

Number of scouting flights for the Pacific Fleet

8

Date of crash

February 11, 1935

Location of crash

Point Sur, California

Lives saved

81

Lives lost

2

Gas volume

6.5 million cubic feet of non-flammable helium stored in 12 large cells made from gelatin-latex fabric

Power plant

8 gasoline powered, reversible Maybach VL-2 12-cylinder water-cooled inline engines (560 hp each), driving three-bladed fixed-pitch, rotable metal propellers

Total horsepower

4,500

Fuel capacity

60 tons

Height

146 feet, 5 inches

Dead weight

108.2 tons

Structure

Duralumin ring frames and girders, covered with a fabric envelope

Top speed

75.6 knots, or 87 miles per hour

Cruising speed

55 knots or 63 miles per hour

Curtiss F9C-2 Sparrowhawk

Key Facts

Length

20 feet, 7 inches

Wingspan

25 feet, 5 inches

Empty weight

2,114 pounds

Loaded weight

2,776 pounds

Cruising speed

125 miles per hour

Range

297 miles

Service ceiling

19,200 feet

Number of Browning .30-caliber machine guns

2